Kunshan Geardee automation equipment Co., Ltd. Provide high-precision hollow rotating platform, alignment platform and planetary reducer!

Service Hotline:

18913269331

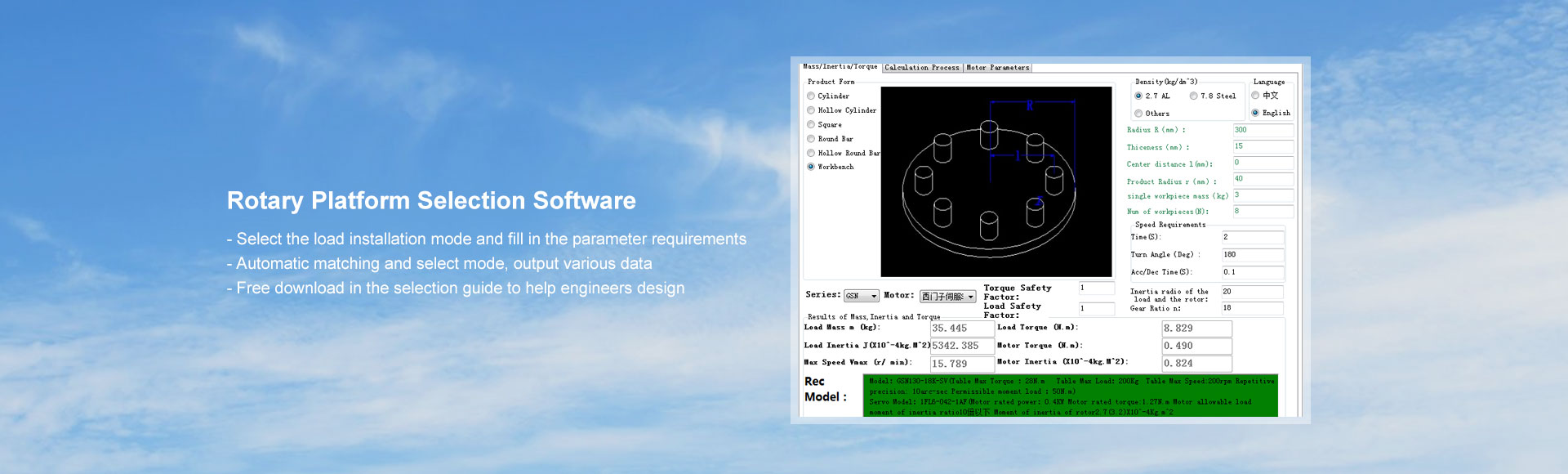

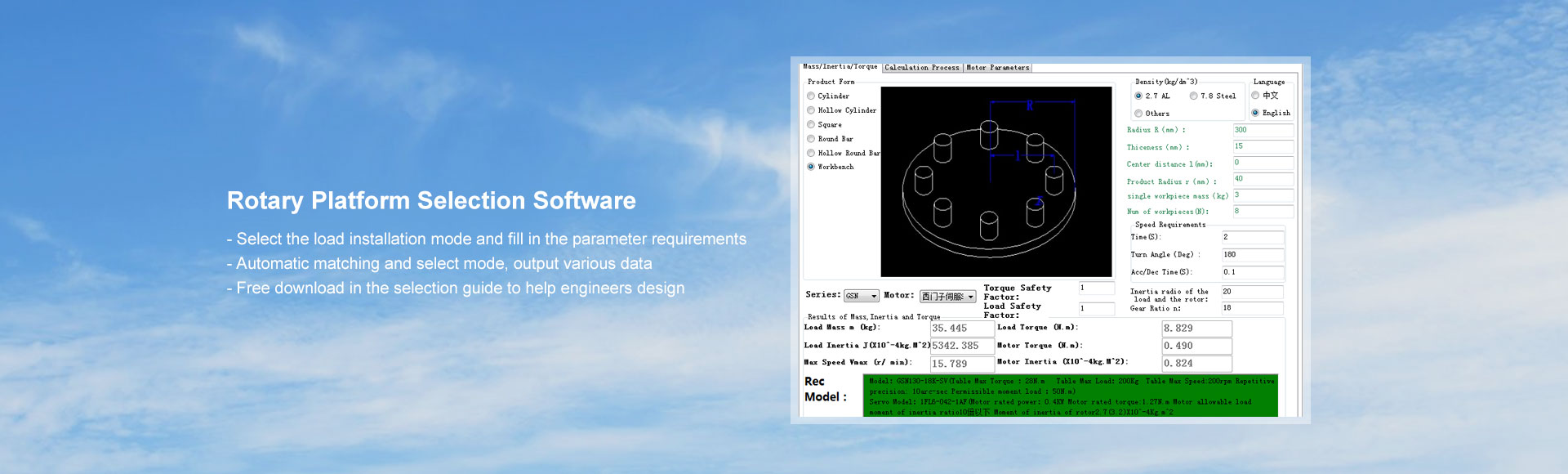

Selection guide

Selection guideSix structural advantages of hollow rotating platform:

I. Hollow structure

The turntable of the hollow rotary platform is a hollow structure, and the middle hole is convenient for the installation of gas pipe and wire. If it is used with multi-channel rotary joint, it can realize continuous rotation and avoid wire winding.

II. High rigidity

The hollow rotating platform is supported by a set of precision cross roller bearings. The bearing of staggered rollers is 90 degrees, and the roller diameter is slightly larger than the raceway size between the inner ring and outer ring of the bearing. The prestress between the inner ring and outer ring of the cross roller bearing and the roller and the support of the servo turntable bear radial, axial and overturning moments, and its stiffness is more than 10 times that of the traditional bearing.

III. High rotation accuracy

After the hollow turntable is assembled, the outer diameter and end face of the turntable are grinded again with the cross roller bearing of the platform as the rotation center.

IV. Flexibly equipped with reduction ratio to achieve high torque

In addition to the body reduction ratio, the hollow rotating platform can adopt the two-stage planetary reduction mode to increase the output torque. Generally, the reduction ratio can reach 3 ~ 200, and the output torque range is large, which can meet various torque requirements.

V. With home switch and optional limit switch

The rotating platform is equipped with in-situ photoelectric switch and installation accessories as standard, and can also be equipped with positive and negative limit switches to facilitate electrical zero control and simplify the mechanical design process.

VI. Dustproof and waterproof

The dustproof and waterproof level of GSH Series hollow rotating platform reaches IP65, which meets the requirements of working in harsh environments such as dust and splash